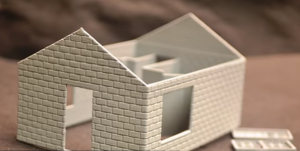

A 3D building printer is a machine that can build houses by depositing a material (e.g., concrete) layer by layer. 3D printing of concrete – aka “Construction 4.0” – is a 3D printing technology similar to that used by 3D FFF (molten wire deposition) printers. Paste material, in this case, concrete or sludge, is pushed through a nozzle to form layers. In the building sector, 3D printing of concrete saves time, money and raw materials .

Indeed, only the frame of the house is built; other items, such as windows, electricity or plumbing, must be installed separately. 3D concrete printers, however, can be used to print bridges, benches, or just outdoor decorations.

Indeed, only the frame of the house is built; other items, such as windows, electricity or plumbing, must be installed separately. 3D concrete printers, however, can be used to print bridges, benches, or just outdoor decorations.

To provide a comprehensive overview of the 3D printer market for construction, we have identified 12 3D home printing solutions.

HOW TO PRINT A HOUSE IN 3D?

HOW TO PRINT A HOUSE IN 3D?

Here we will elaborate on how 3D printers can print houses in 3D through the extrusion of dough.

The technology used for 3D printing of houses

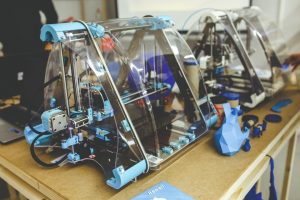

3D printers in the house use extrusion technology. Some 3D building printers resemble FFF / FDM desktop 3D printers (Gantry or Gantry type), while others consist of a mechanical arm swiveling on itself.

In both cases, pasty material such as concrete is used as filament. The content is pushed through a special nozzle to form layers. Simply put, the extrusion of dough can be compared to the use of a pastry bag to spread icing on a cake.

…